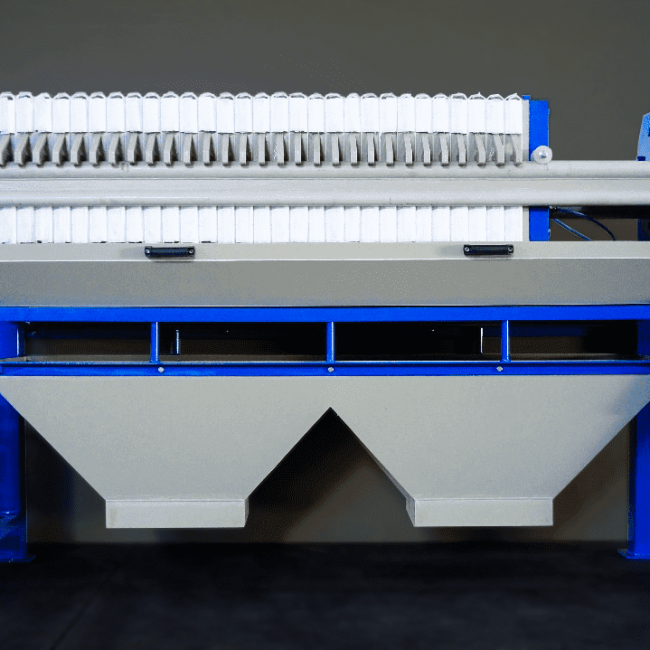

Filter presses are widely used in the effluent treatment process. Their function is to dehydrate the effluent, reducing the volume of generated sludge, preventing the settling and transport of water, resulting in a significant decrease in the disposal costs of solid waste from the process.

LJ Santos’ filter presses are versatile and safe, easy to operate, and require simple and quick maintenance. They have low electricity consumption, making them an excellent solution in the effluent treatment process with an optimal cost-benefit ratio.

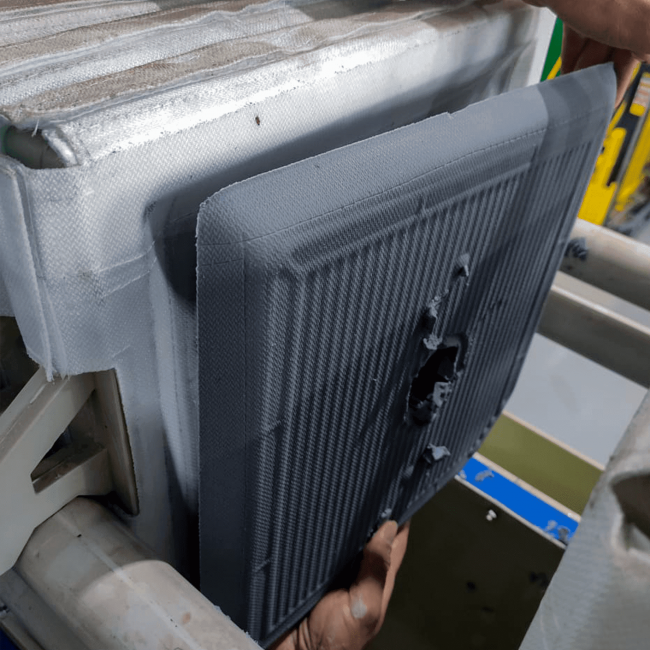

Filter presses are robust equipment, designed to perform solid/liquid separation. The solution with waste is pumped against filter cloths, which only allow the liquid part of the solution to pass through. This liquid part is drained, already free of solids, through channels present in the filter plates.

Meanwhile, the solid part is continually deposited on the canvas, forming an increasingly thick layer. The filter plates have a profile that allows the formation of chambers inside the equipment, completely filled with solids.

When pumping under high pressure, the particles settle to generate compact cakes with a low level of moisture. Thus, filter presses guarantee efficient dehydration of the effluent, reducing the volume of sludge generated.

Contact